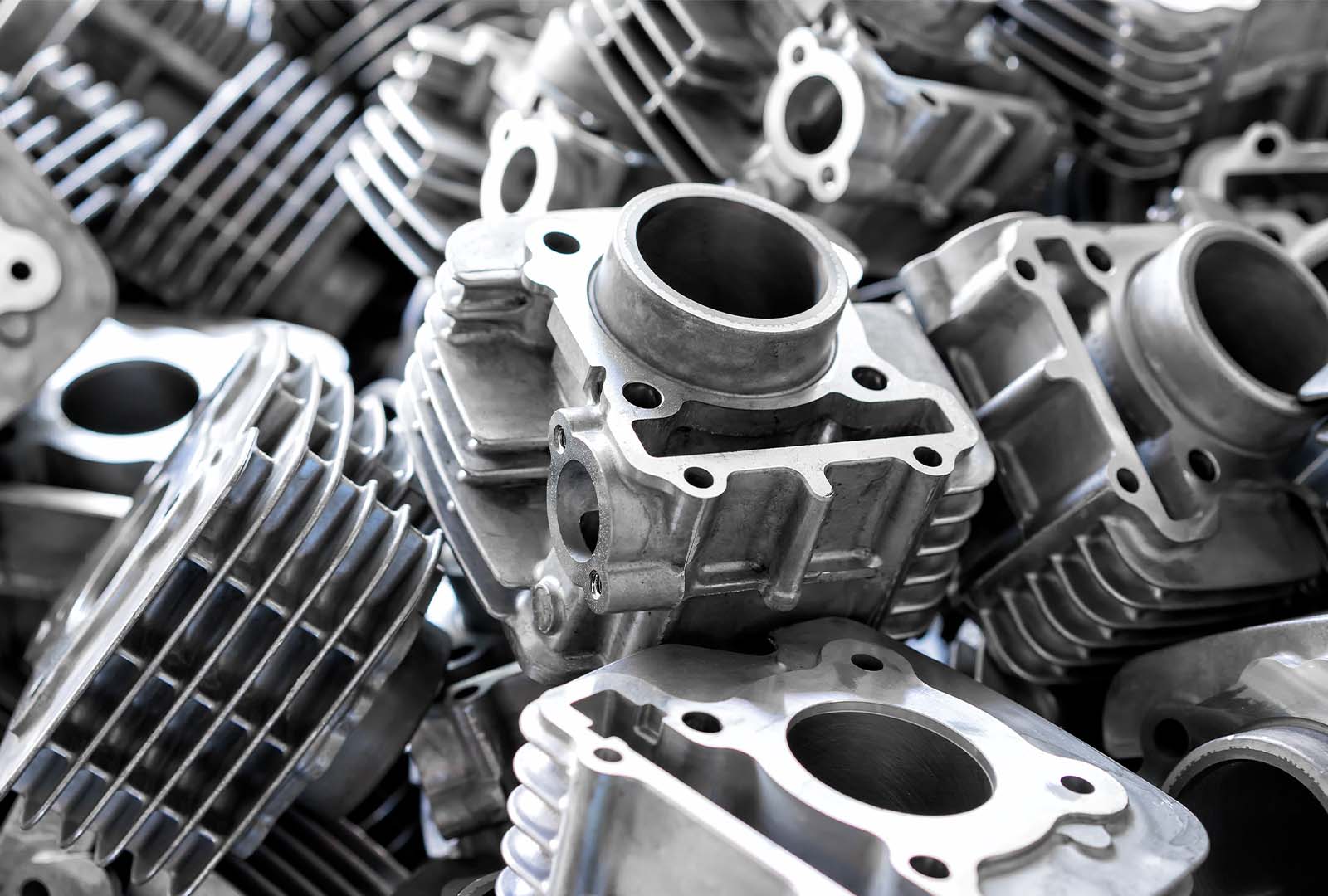

Diecasting has become a significant pillar of Malaysia’s manufacturing sector, playing a key role in producing high-quality metal components for various industries. The process of diecasting involves forcing molten metal into a mold under high pressure to create intricate parts with exceptional precision. This method is favored for its ability to produce consistent, durable components that are used in everything from automotive parts to electronics and home appliances. In Malaysia, diecasting has evolved into a highly specialized industry, with many companies adopting advanced technologies to meet the growing demand for precision manufacturing.

One of the main factors behind the growth of diecasting in Malaysia is the increasing demand for lightweight, high-strength metal components, particularly in the automotive and electronics industries. The automotive sector, in particular, relies heavily on diecasting to produce parts that are both strong and lightweight, which is essential for improving fuel efficiency and reducing emissions. Similarly, the electronics industry benefits from diecasting’s ability to create small, complex components with high dimensional accuracy. As these industries continue to grow in Malaysia, the diecasting sector has expanded in parallel, positioning the country as a key player in the global supply chain for precision metal parts.

Technology and innovation have played a critical role in enhancing the diecasting industry in Malaysia. Many companies have invested in state-of-the-art equipment, such as computer-controlled diecasting machines and automated production lines, which improve both efficiency and product quality. These advancements have allowed manufacturers to meet the stringent quality standards required by industries like aerospace and telecommunications, where precision and durability are paramount. Additionally, innovations in materials science have led to the development of new alloys and coatings that enhance the performance of diecast parts, making them more resistant to wear, corrosion, and extreme temperatures.

Sustainability has also become a focal point in diecasting malaysia industry, reflecting the global shift towards more eco-friendly manufacturing practices. Diecasting is an inherently efficient process, as the metal used in the process can be recycled multiple times without losing its integrity. Many Malaysian diecasting companies have adopted recycling programs and energy-efficient production techniques to minimize waste and reduce their environmental impact. The industry is also exploring the use of alternative materials, such as magnesium alloys, which are not only lighter but also more environmentally friendly than traditional metals like aluminum and zinc.

Despite the many advantages of diecasting, the industry in Malaysia faces several challenges. One of the primary hurdles is the rising cost of raw materials, particularly aluminum and zinc, which are commonly used in diecasting. Fluctuating global prices for these metals can significantly affect the profitability of diecasting operations. Additionally, the industry must constantly adapt to new technological advancements and changing market demands. As industries such as automotive and electronics continue to innovate, diecasting companies must stay ahead by investing in research and development to keep pace with new requirements for precision, durability, and sustainability.

In conclusion, diecasting in Malaysia is a critical component of the country’s manufacturing sector, supporting a wide range of industries with high-quality metal components. The industry’s success is driven by its ability to produce precise, durable parts efficiently and at scale, making it an essential part of the global supply chain. As technology and sustainability become increasingly important in manufacturing, Malaysia’s diecasting industry is well-positioned to continue growing and evolving. However, it must also navigate challenges such as rising material costs and the need for constant innovation. With continued investment in technology and sustainable practices, diecasting in Malaysia will remain a key player in precision manufacturing for years to come.